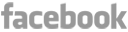

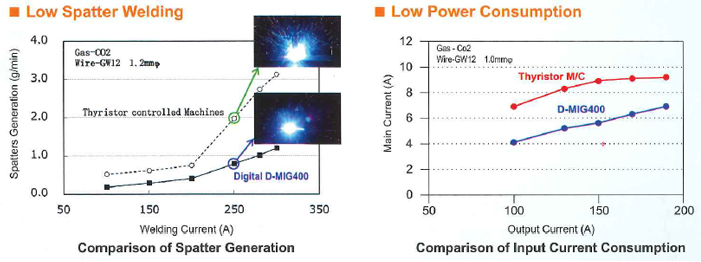

Reduced Electricity Cost due to high power factor & low input current.

Synergic Control

One - Knob Synergic Control Provides Appropriate ARC Voltage for the Welding current Selected.

Easy Operation

Less Buttons and Digital Setting / Digital Indicator.

Assured Quality

Cutting edge "Penetration Control" is one flip of the knob away.

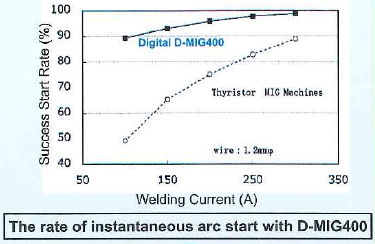

Fine ARC Start

Instantaneous ARC Start Close to 100% From Low to High Current.

Programmable

Up to 30 welding conditions can be stored, 10 regular used conditions can be read and operate from remote control box.

One-Knob Synergic Control Provides Appropriate Arc Voltage for the Welding Current Selected

Un-xperienced Operators Can Achieve Proper Welding Conditions Without Creating Rework.

The Machine Delivers a Built in Preset Voltage Program to Accommodate the Amperage.

(Wire Feed Speed)

Separate Control Mode (for Amperage & Voltage) is Also Provided as a Standard Feature.

Easy to Read and Precise Current/Voltage Scales on Remote Control

Indicates adjusted value due to the effect of the gas mixture and wire diameter.

Microprocessor controll allows instantaneous arc start even at low current virtually every time. And it features Hot Start and Wire Slow Down Start control. This combination delivers secured arc starts.

Wire Feed roll 0.8 - 1.2 mm standard

Easy to Set V & I by operator at his work.

Less trouble.

Standard remote control for convenience. (3m cable)

It allows adjustment of welding conditions at the work.

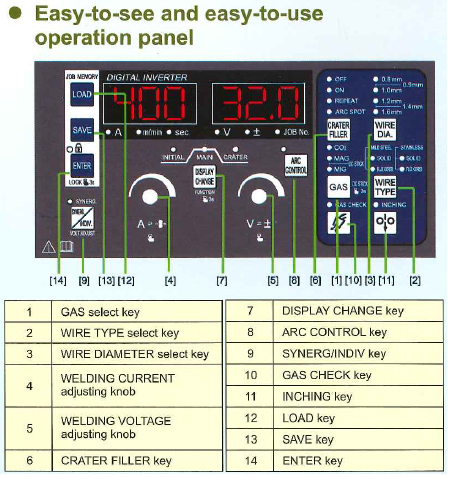

• Simple and user-friendly operation panel.

• Crater fill function prevents crater cracking at the end of weld.

• Initial current control.

• 100V(2A) power outlet equipped for shielding gas regulator heater.

• Preheating fucntion.

• Mice proof case.

• Terminals for automatic machine.

• Operation prevention due to lost input power phase.

• High Power Factor (0.9 & above)

• 30 Program Memory Storage facility.

• DC stick welding possible

Power saving design

• Shielding gas saving function

• On demand cooling fan

(Not applicable if preheating function is used.)

• Power saving sequence

(Not applicable if preheating function is used.)

• No load powerless than 150 watts

Safety design

• Thermostat for preventing overheating.

• Low voltage drive of wire feder for 24VDC.

• Single Phase Protection.