SDB 103 | SDB 206 | SDB 412

Wachs SDB 103/3 is a hand held beveling machine that delivers maximum power and performance for fast, accurate weld preps. The machine operates on pipe and tube from .875" I.D. through 4.5" O.D. (22.2mm to 114.3mm). Face, bevel and counterbore simultaneously on carbon, stainless and high alloy steels. Benefit from the SDB’s versatility. Machine boiler tube, heavy wall pipe, thin wall tube, prep elbows and face flanges with the SDB 103/3.

• Aluminum alloy casting is tough yet lightweight.

• Precision tapered roller bearings and self lubrication bushings maximize machine life.

• Four-tool. rotating head with large, easy-to- access tool locking set screws.

• High strength, large diameter mandrel and wide profile chuck legs to maximize rigidity.

• Dual key design makes tool feed easy. absorbs torque and reduces operator fatigue.

• "Quick Change" extension legs use captivated fasteners.

• Standard mandrel covers a broad size range from 1.16" ID. to 4.5" O.D.(29.4-114.3 mm)

• Right angle air motor placement minimizes clearance requirements.

• Lightweight for easy handling. Set up and operate from storage case to pipe in 5 minutes.

• Bevels 2" schedule 80 stainless steel pipe in less than one minute.

• Simple Operation: Convenient on/off motor valve. adjustable hand grip speed control and in-feed hand wheel with indices for precise measurement.

• Single adjustment, universal three leg chuck automatically centers the machine into pipe ID.

• "Easy Release" chuck retracts smoothly for fast machine removal from pipe.

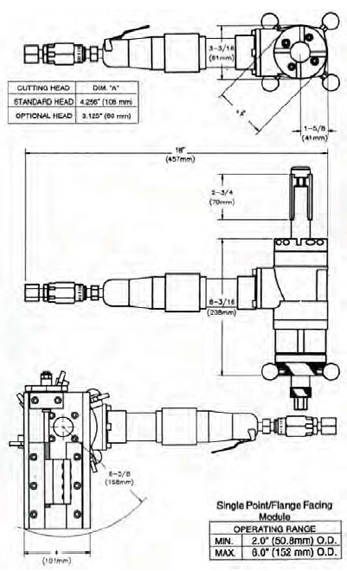

Machining Function : portable pipe prepping machine: face. bevel. compound bevel. j prep. and counterbore using up to 4 tools simultaneously. Machine flat face and raised face flanges, record groove (500 rms). 250 rms. 125 rms. and 63 rms surface finishes with optional flange facing module.

Capacity : machine pipe and tube sizes 7/8" 1.0. through 4.5" (22.2-1143 mm) 0.0. Face flanges 2.0" through 6.0" (508-152 mm) 0.0. using single point flange facing module.

Controls : manual tool in-feed with indices. Standard on/off valve. hand grip speed control (air motor).

Feed : manual. indexed feed dial with removable feed handles ° 2.5" (63.5 mm) maximum feed (std. mandrel). 0.0625" (1.5 mm) per revolution.

Mandrels :

• standard mandrel.1.16" to 4.16" (294-1056 mm) I.D.

• small mandrel. .875" to 1.250" (22.2 - 31.7 mm) I.D.

• independent fitting mandrel. 1.95" to 4.11" (49.5 104.3 mm) I.D.

• collet mandrel. for tube and pipe 1.375" to 4.378" (34.9 - 111.1 mm) 1.0.

Drive : Pneumatic or electric.

Air Requirements : 35 cfm @ 90 psi (1.0 m3 @ 6.3 bar).

Air Motor : 160 rpm free speed - develops 160 ft.-lbs. torque.

Tooling : ground and coated t-15 high speed steel form tools to face. bevel and counterbore. Carbide and custom configuration Wachs tooling available. Weight: 503 103/3 with standard cutting head and standard mandrel: 20 lbs. (9.08 kg).

Finish : powder coat (red).

WARRANTY

E.H. Wachs Mchine Tools and their associated parts are warranted against defects in materials and workmanship for a period of twelve months from the date of purchase.

EH. Wachs Company reserves the right to repair or replace only those parts which prove to have been defective at the time of purchase. This warranty becomes void if maximum flow and pressure ratings are exceeded.